laser technology

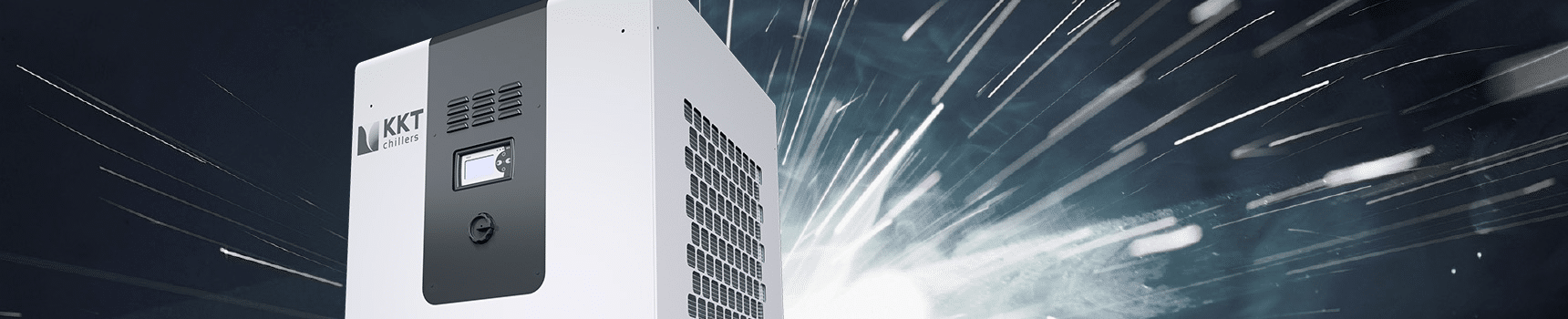

Custom laser chiller technology from KKT Chillers to help you protect your investments

optimal performance for lasers in 3d printing, welding, laser perforation

– and more

Lasers have become increasingly popular in various applications, particularly 3D printing, welding, and laser perforation. The success of any of these processes relies heavily on temperature control. Without proper temperatures, your laser system could be damaged or experience reduced output.

The best way to prolong the life of your laser systems? KKT laser chillers to cool your whole system.

Chiller Applications for Laser Technology

See how our chillers have been employed to assist with laser technology applications in the real world

How a Chiller Benefits Your Laser System

At KKT Chillers, we believe in providing our customers with the best technology to ensure their investments are protected and working at peak performance. That’s why we developed custom laser chiller technology that is designed specifically for the needs of laser equipment.

When you invest in a high-quality chiller, you can expect:

- Increased laser performance & output

- Improved life span of the laser systems

- Lower energy consumption costs associated with cooling

- Decreased need for frequent maintenance services or repairs

- Enhanced safety in applications where heat can be hazardous

Should You Use A Water- Or Air-Chilled Chiller?

Choosing the right chiller for your laser systems depends on several factors. For example, if you’re using a high-powered laser system, water-cooled chillers may be more suitable as they can usually handle greater heat loads with more efficiency.

On the other hand, air-cooled chillers are easier to install and provide a higher degree of flexibility. They are also less expensive to operate and maintain, so they may be better in environments with a lower power output and more limited cooling requirements.

If you need help deciding, our knowledgeable customer service team is here to help. All of our laser chillers are backed by an extensive warranty, so you can trust that your investment is secure.

Should You Use A Water- Or Air-Chilled Chiller?

Our custom laser chillers provide a reliable and effective cooling system for lasers, allowing them to maintain optimal temperatures to deliver the best performance and most efficient operation.

We believe in delivering the highest quality products at competitive prices, so you can trust that you’re getting the best value for your investment. Since 1978, our clients have relied on us for their laser cooling needs, and we continue to provide the same excellent customer service today.

From our foundational models to our more complex, custom orders, our team supports you with design, installation, maintenance, and training. Contact us today to learn more about how our chillers can improve your laser performance.